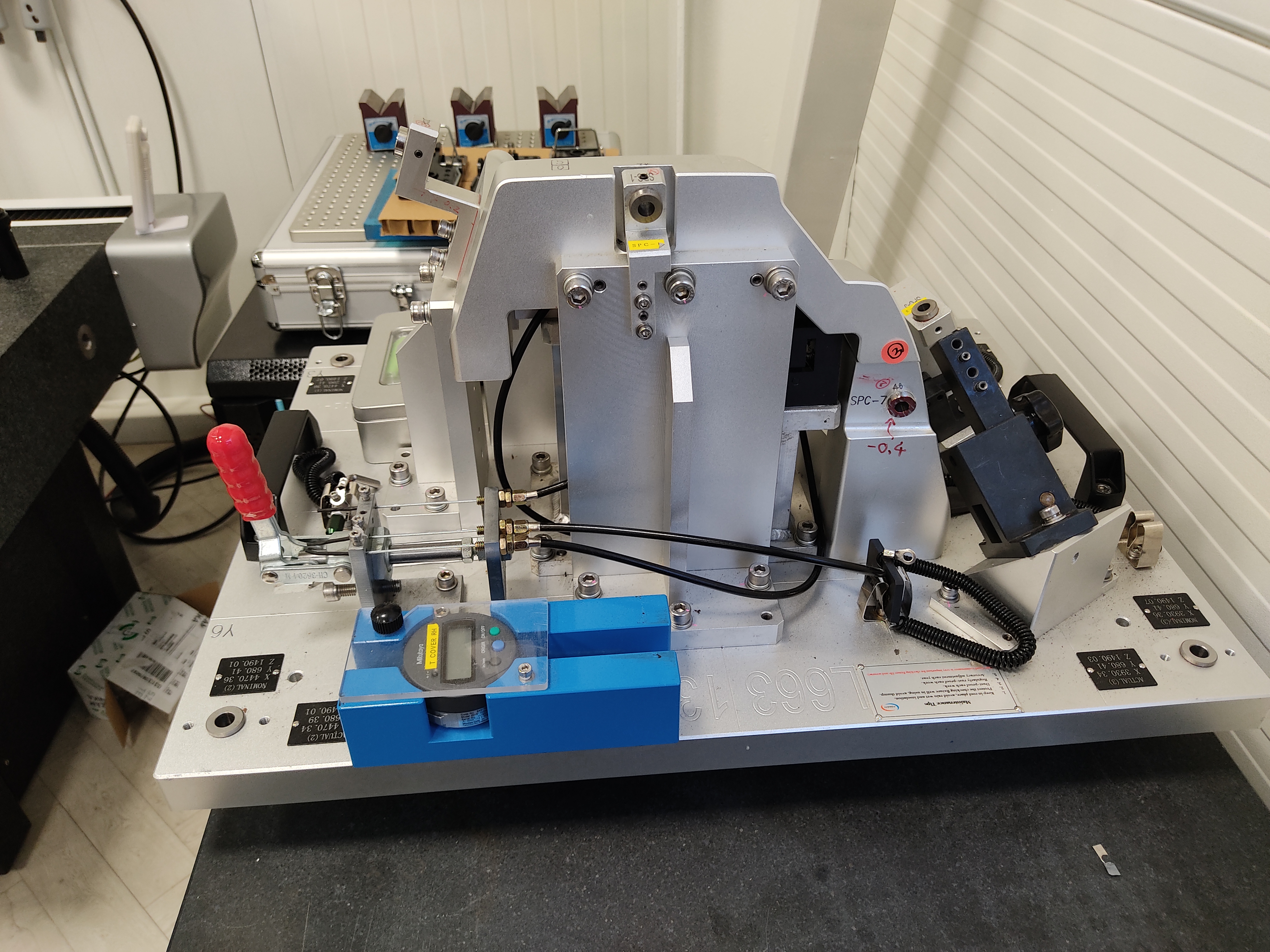

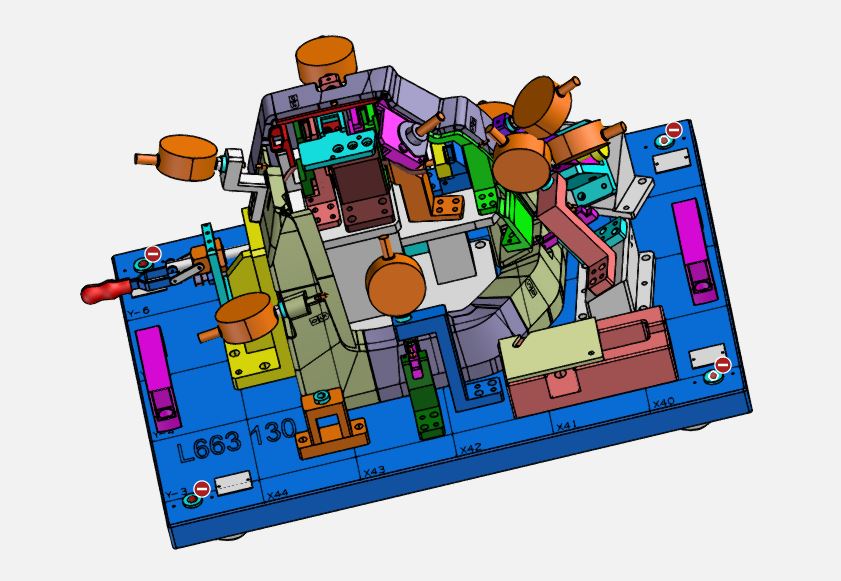

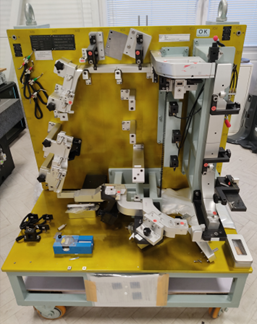

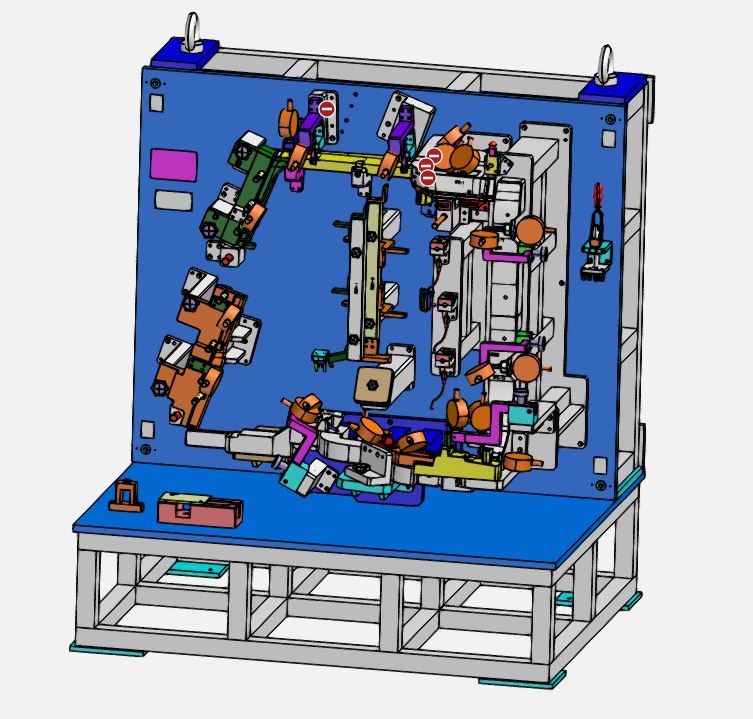

Measurement JIG designing and manufacturing

About General Gauge Design:

"Gauge design" refers to a process where a specialized template or tool is designed and created to aid in the accurate measurement, fitting, or other measurement tasks of various dimensions and distances. Gauge templates are frequently used in manufacturing and measurement processes, where precise dimensions and fits need to be checked or ensured.

Gauge templates can be physical tools such as measuring tapes, scales, or specially shaped templates that can be placed directly on the object to read measurements. These templates contain predefined measurements that allow for quick and accurate verification of the object's dimensions.

In some cases, gauge design and manufacturing can be software-based, using 3D modeling programs, for example. With the help of these software tools, predefined measurements, fits, and distances can be set in the planned gauge template, which assists in performing measurement tasks.

The design of gauge templates is important in manufacturing processes and quality control as they enable quick and accurate measurements, fits, and inspections. Additionally, gauge templates make measurement tasks easier and more efficient, contributing to improving the quality and accuracy of products.

JIG:

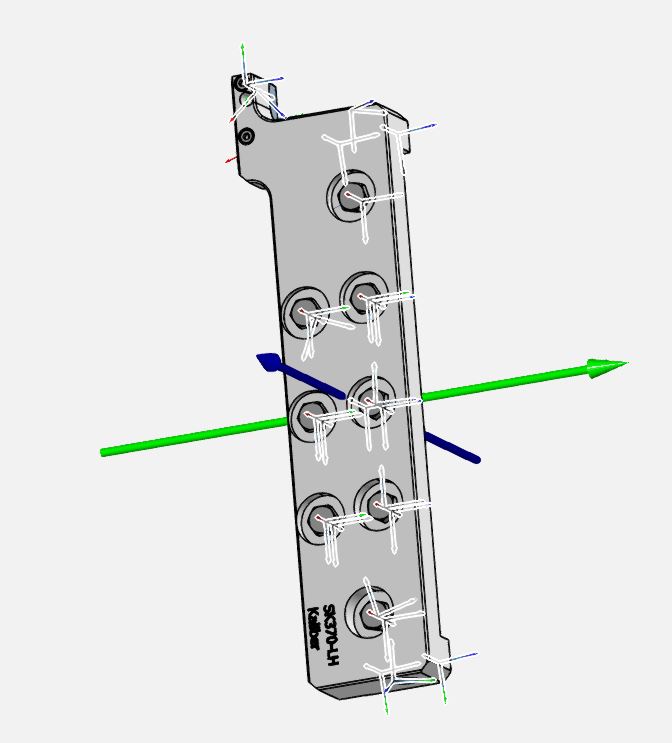

JIG, also known as a fixture, is a device used to hold and guide workpieces during manufacturing or assembly processes.

Its primary purpose is to ensure precise positioning, alignment, and fixation of the workpiece, allowing for consistent and accurate production or assembly.

JIGs are commonly used in manufacturing and assembly lines to maintain uniformity and improve efficiency in the production process.

JIGs can be temporary or permanent fixtures and are often custom-designed for specific manufacturing tasks.

They may include locators, clamps, guides, or other components that facilitate the proper positioning of workpieces.

Measuring Gauge:

A measuring gauge, on the other hand, is a specialized tool used for measuring dimensions, distances, or features of objects or workpieces.

Its primary purpose is to verify the accuracy and conformance of the dimensions or features of the workpiece with the required specifications or standards.

Measuring gauges are commonly used in quality control and inspection processes to ensure the products meet the required standards.

Measuring gauges can be both simple handheld tools, such as calipers or micrometers, or more complex equipment like coordinate measuring machines (CMM) for precise 3D measurements.

They are designed to provide accurate and repeatable measurements, allowing for quality assessment and adherence to specifications.

In summary, a JIG is a device used for positioning and guiding workpieces during manufacturing or assembly, while a measuring gauge is a tool used for verifying and measuring dimensions or features of objects. While they may be used together in some situations, their primary functions and purposes are distinct.