Reverse Engineering

About Reverse Engineering in General:

In metrology, "reverse engineering" is a process where the operation and structure of a finished product, equipment, or system are deciphered without having access to the original design documentation or specification. The aim is to understand the functioning and characteristics of the given tool or system without physically dismantling it as prescribed by the manufacturer.

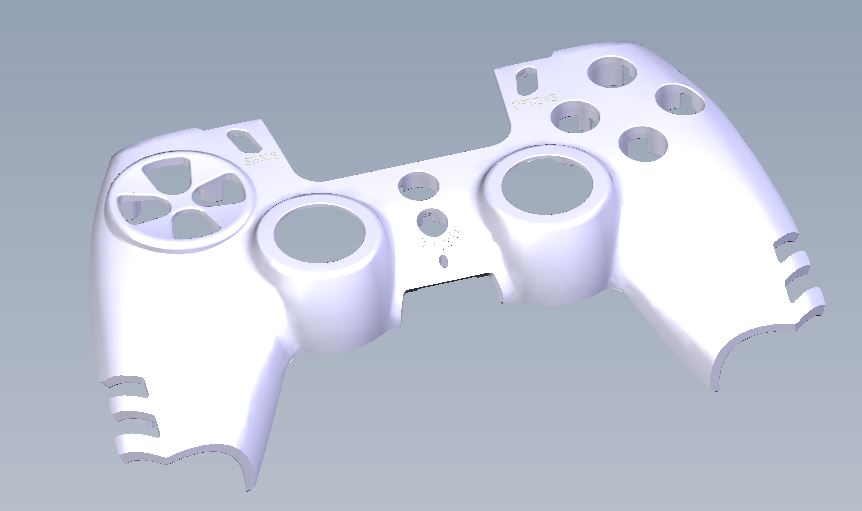

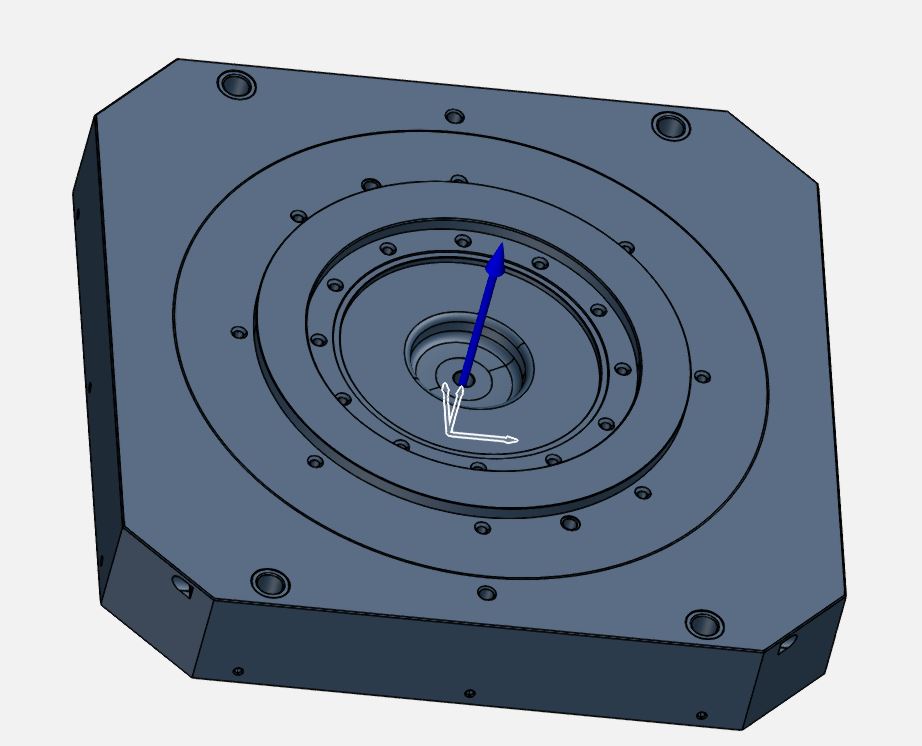

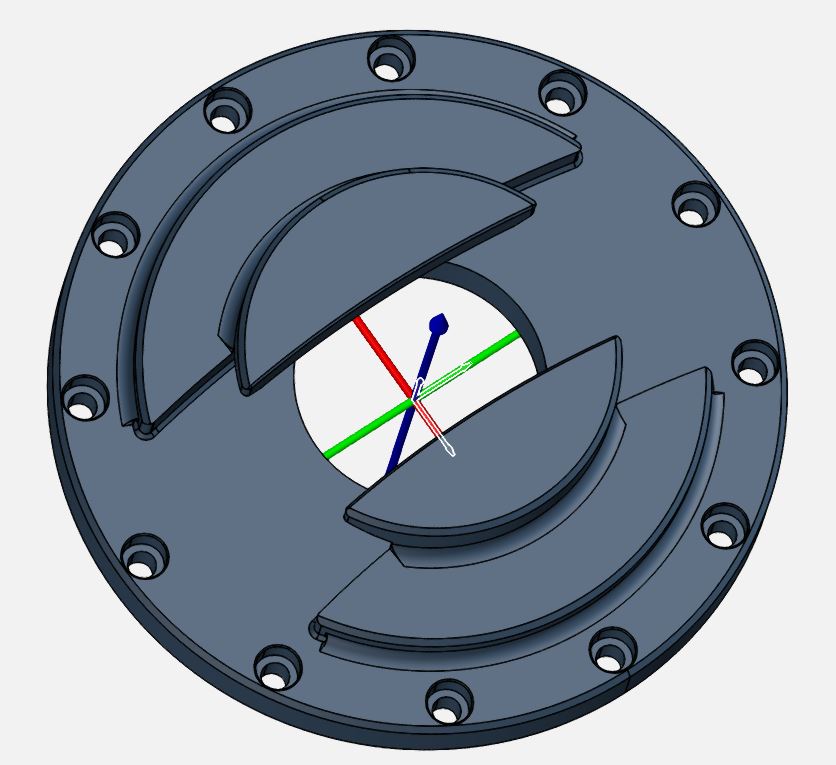

This procedure allows for the creation of an accurate digital model of the original object without the need for direct replication or access to the design documentation.

Various techniques and tools can be employed during 3D scanning to record the precise geometry and surface properties of the object. Some of these techniques include:

- CT Scanning: In the industry, CT scanning is a technology known internationally as "Computed Tomography" (CT) industrial application. This technology is based on similar principles as medical CT scanning but is used for examining and analyzing various materials and products.

During industrial CT scanning, the product or component is rotated within a specialized device (CT scanners) while X-rays generate cross-sectional images of it. Subsequently, the computer processes the data to create a point cloud representing the detailed examination of the product or component. - Laser Scanning: This technique employs laser beams to scan the surface of the object, creating a point cloud representation. The laser scanner projects a laser beam onto the object's surface, and the reflected beams are detected. The collected data is then used to create the object's point cloud model.

- Structured Light Scanning: Another method involves projecting structured light patterns onto the object, and a camera captures the pattern from the object's surface. The obtained data allows the software to create a 3D model of the object.

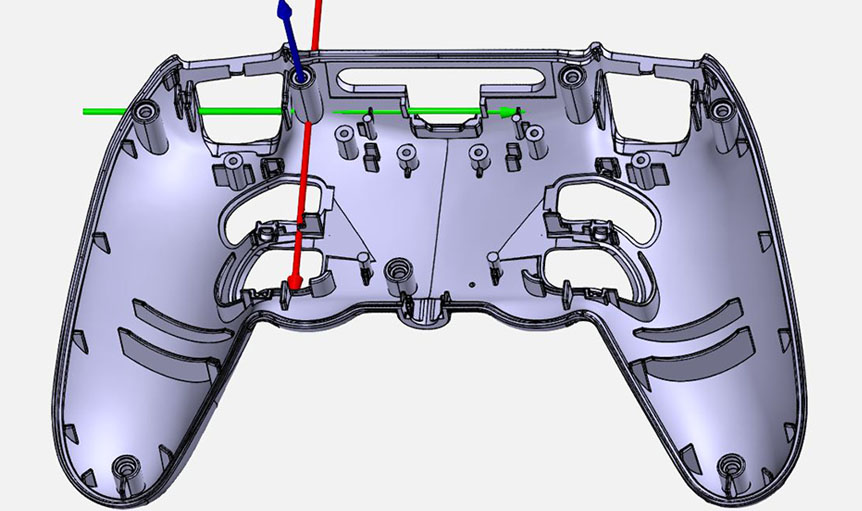

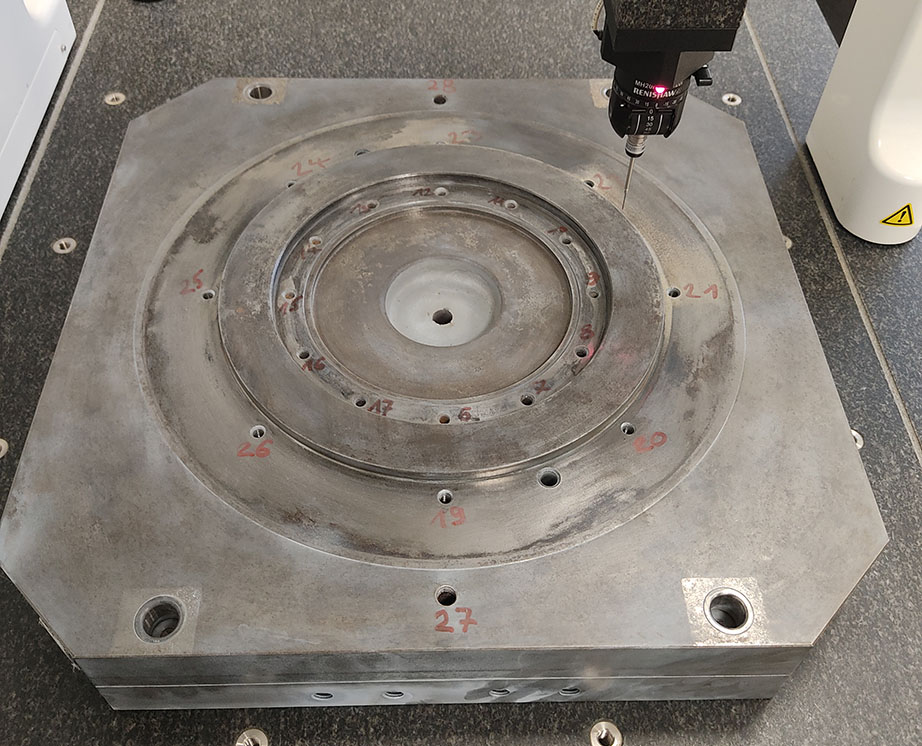

- Coordinate Measurement: Coordinate measurement is an industrial measurement technique used to determine the position and dimensions of points or geometric elements on an object or component's surface. This measurement method is crucial in manufacturing processes, as it enables precise verification and assessment of the dimensions and fit of components and products.

Coordinate measurement utilizes specialized measuring devices, such as coordinate measuring machines (CMM). A CMM is an instrument capable of measuring three-dimensional points in space and recording their coordinates. The measurement points are typically detected using touch or non-contact sensors.

Applications of Reverse Engineering and 3D/CT Scanning in the Industry may include:

- Maintenance of an old, no longer manufactured equipment without available documentation.

- Lack of information from the original manufacturer about the structure or operation of the equipment.

- Repairing a malfunctioning product without physical disassembly.

- Analyzing competitor's products to facilitate improvements or developments in one's own product.